JOTP-011

5 December 2014

APPENDIX A. BACKGROUND/RATIONALE

ANNEX 1. ENVIRONMENTAL TESTS

A.1-1.4 Temperature Stabilization.

For environmental tests that require temperature conditioning, temperature stabilization is

achieved when the part of the item considered to have the longest thermal lag is changing no more

than 2 °C per hour. Since it may not be practical to monitor the interior parts of a live munition

with the longest thermal lag during test without damaging seals, the stabilization time may be

determined prior to live munition testing using an instrumented thermally equivalent inert

munition. The stabilization time will typically be required for the munition in both the unpackaged

and the transport configurations and at the hot and cold temperature extremes. As an alternative,

see Table A-1 for minimum stabilization time values. Care should be taken that no item exceeds

the safe life of the energetic material when subjected to multiple exposures of high temperature

conditioning.

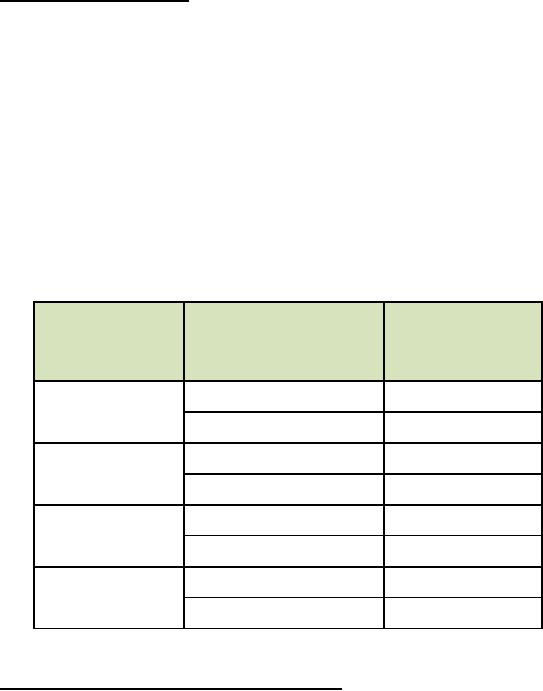

TABLE A-1. DEFAULT TEMPERATURE STABILIZATION TIMES

Minimum

Munition

Temperature

Diameter (D)

Configuration

Stabilization Time

(cm)

(hours)

Unpackaged

12

D ≤ 12.7

Packaged/Palletized

24

Unpackaged

24

12.7 < D ≤ 25.4

Packaged

36

Unpackaged

48

25.4 < D ≤ 38.1

Packaged

60

Unpackaged

60

> 38.1

Packaged

72

A.1-1.5 Solar Radiation Equivalent (SRE) Temperature.

As an alternative to installing solar lamps in a vibration test chamber, the solar radiation equivalent

(SRE) temperature is specified in most mechanical environment tests in order to facilitate testing.

The SRE is the maximum temperature value experienced by the energetic material (e.g., rocket

motor propellant, warhead main charge) after exposure to direct or indirect solar radiation.

Determination of this value will require exposure of an inert, internally instrumented munition,

with similar thermal characteristics to the complete round, to the full solar test requirement defined

in Appendix C, Annex 1, Paragraph C.1-5. The SRE temperature should be determined for both

the packaged and unpackaged state, and applied for all mechanical environment tests such that the

A.1-2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business