JOTP-011

5 December 2014

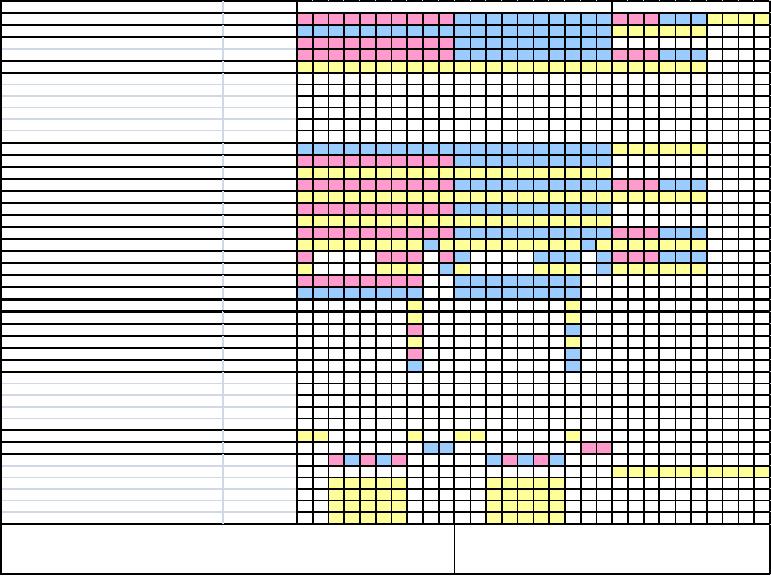

APPENDIX B. TEST PROGRAM FOR SURFACE AND UNDERWATER LAUNCHED MUNITIONS

ANNEX 1. ANALYTICAL S3 TEST PROGRAM

TABLE B1-2. SEQUENTIAL TEST ROUND ALLOCATION TABLE FOR THE S3 ANALYTICAL TEST PROGRAM

Munition number

(Live Munitions)

Motor Case Sequence (Inert)

Test serial

App/Annex/Para

1

2

3

4

5

6

7 8 9 10

11 12 13 14

15

16

17

18

19

20

1

2 3 4 5 6 7 8 9 10

Level 2 Inspection (BIT, visual, NDT, radiography)

7.3

c

c

c

c

c

c

cccc

cccc

c

c

c

c

c

c

a

aaaaa

Common carrier vibration

C/2/1.1

h

h

h

h

h

h

hhhh

cccc

c

c

c

c

c

c

Packaged transit drop

C/3/1

h

h

h

h

h

h

hhhh

cccc

c

c

c

c

c

c

h

h

h

c

c

c

Level 2 Inspection (BIT, visual, NDT, radiography)

7.3

a

a

a

a

a

a

aaaa

aaaa

a

a

a

a

a

a

a

a

a

a

a

a

Humid heat

C/1/1

x

x

x

x

x

x

xxxx

xxxx

x

x

x

x

x

x

x

x

x

x

x

x

Low temperature storage

C/1/2

x

x

x

x

x

x

xxxx

xxxx

x

x

x

x

x

x

x

x

x

x

x

x

High temperature storage

C/1/3

x

x

x

x

x

x

xxxx

xxxx

x

x

x

x

x

x

x

x

x

x

x

x

High temperature cycling

C/1/4

x

x

x

x

x

x

xxxx

xxxx

x

x

x

x

x

x

x

x

x

x

x

x

Solar radiation

C/1/5

x

x

x

x

x

x

xxxx

xxxx

x

x

x

x

x

x

Thermal shock

C/1/6

x

x

x

x

x

x

xxxx

xxxx

x

x

x

x

x

x

Level 2 Inspection (BIT, visual, NDT, radiography)

7.3

c

c

c

c

c

c

cccc

cccc

c

c

c

c

c

c

a

a

a

a

a

a

Sea Transport Dynamics

C/2/3

h

h

h

h

h

h

hhhh

cccc

c

c

c

c

c

c

Level 2 Inspection (BIT, visual, NDT, radiography)

7.3

a

a

a

a

a

a

aaaa

aaaa

a

a

a

a

a

a

Air Transport Dynamics - Military

C/2/4

h

h

h

h

h

h

hhhh

cccc

c

c

c

c

c

c

h

h

h

c

c

c

Level 2 Inspection (BIT, visual, NDT, radiography)

7.3

a

a

a

a

a

a

aaaa

aaaa

a

a

a

a

a

a

a

a

a

a

a

a

Land Transport Dynamics - Military

C/2/2

h

h

h

h

h

h

hhhh

cccc

c

c

c

c

c

c

Level 2 Inspection (BIT, visual, NDT, radiography)

7.3

a

a

a

a

a

a

aaaa

aaaa

a

a

a

a

a

a

Tactical Combat Platform Dynamics

C/2/5

h

h

h

h

h

h

hhhh

cccc

c

c

c

c

c

c

h

h

h

c

c

c

Level 2 Inspection (BIT, visual, NDT, radiography)

7.3

a

a

a

a

a

a

aaca

aaaa

a

a

a

a

c

a

a

a

a

a

a

a

Tactical Drop

C/2/6

h

h

hh

h

c

c

c

c

c

h

h

h

c

c

c

Level 2 Inspection (BIT, visual, NDT, radiography)

7.3

a

a

aa

c

a

a

a

a

c

a

a

a

a

a

a

Munition Flight Dynamics

C/2/10

h

h

h

h

h

h

hh

cccc

c

c

c

c

Level 2 Inspection (BIT, visual, NDT, radiography)

7.3

c

c

c

c

c

c

cc

cccc

c

c

c

c

Cargo Aircraft Rapid Decompression

C/1/12

a

a

Level 2 Inspection (BIT, visual, NDT, radiography)

7.3

a

a

Rail Impact

C/2/1.3

h

c

Level 2 Inspection (BIT, visual, NDT, radiography)

7.3

a

a

Rough Handling Transit Drop**

C/2/7

h

c

Level 2 Inspection (BIT, visual, NDT, radiography)

7.3

c

c

Salt fog

C/1/8

x

Sand & dust

C/1/9

x

Rain/watertightness

C/1/10

x

Immersion/Pressurization

C/1/7

x

Icing

C/1/11

x

Level 3 Inspection (Full BTCA)

7.4

a

a

a

a

a

a

Dynamic Firing Tests*

D/1/1

c

c

h

h

Rocket motor static firing

D/2/1

h

c

h

c

h

c

h

c

h

c

Rocket motor burst

D/2/2

a

a

a

a

a

a

a

a

a

a

Other pressure vessel burst integrity

D/2/3

a

a

a

a

a

a

a

a

a

a

Warhead Level 2 Inspection (component level)

7.3

a

a

a

a

a

a

a

a

a

a

Other energetic static fire

D/2/5

a

a

a

a

a

a

a

a

a

a

Other safety critical components operational

D/2/6

a

a

a

a

a

a

a

a

a

a

* For canistered munitions with ripple/rapid firing capability, at least 4 dynamic firings are required to test for safe

separation from the launch platform. This can be reduced to 2 dynamic firings for single munition launch canisters.

a = ambient test

c = cold conditioned test

Key:

The dynamic firing tests may be eliminated, if safe separation does not need to be demonstrated.

h = hot conditioned test

x = test temperature defined in test

** If munition survives the drop test determine whether to dispose of the munition or to disassemble for BTCA.

B.1-7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business